how to identify low carbon steel Low carbon steel vs high carbon steel

Low Carbon Steel vs High Carbon Steel When it comes to choosing the right material for your construction or engineering needs, choosing between low carbon steel and high carbon steel is a decision that will greatly impact the quality and performance of your project. Let’s take a closer look at the differences between these two types of steel. Low carbon steel, as the name suggests, has a low carbon content, typically ranging from 0.05% to 0.25%. It is a popular choice for applications that require low strength and high ductility, such as automotive bodies, wire products, and structural steel. Low carbon steel is easily machinable, formable, and weldable, making it ideal for most welding applications. On the other hand, high carbon steel contains a higher percentage of carbon, typically ranging from 0.6% to 1%. This type of steel is known for its strength, durability, and hardness. High carbon steel is commonly used in applications that require extreme hardness, such as knives, saw blades, and springs. While high carbon steel is much stronger than low carbon steel, it is also much more brittle and difficult to work with. When choosing between low carbon steel and high carbon steel, it’s important to consider the specific requirements of your project. If you need a material that is easy to work with and has good ductility, low carbon steel may be the best choice. However, if you need a material that is incredibly strong and durable, high carbon steel may be the better option. Normalised Carbon Steel Normalised carbon steel is another popular type of steel that is commonly used in the construction and engineering industries. This type of steel is made by heating the steel to a specific temperature and then allowing it to cool in air. Normalising helps to refine the grain structure of the steel, making it stronger and more ductile. Normalised carbon steel is often used in applications that require high strength and good ductility, such as pressure vessels, boilers, and structural steel. It is also commonly used in the oil and gas industry, where it is used to make pipelines, drilling equipment, and other critical components. Overall, choosing the right type of steel for your project is essential for achieving the desired performance and durability. When choosing between low carbon steel, high carbon steel, and normalised carbon steel, it’s important to consider the specific requirements of your application and select the material that will provide the best performance and longevity. So, whether you’re a construction professional or an engineer, take the time to carefully evaluate your options and select the right type of steel for your project. By doing so, you’ll be able to create a finished product that is strong, reliable, and built to last.

If you are looking for Low Carbon Steel vs High Carbon Steel you’ve came to the right web. We have 5 Pictures about Low Carbon Steel vs High Carbon Steel like What are Properties of Medium-carbon Steel - Definition | Material, How to identify Carbon Steel by Grinding-Low or High Carbon # and also What is Composition of Low-carbon Steel - Definition | Material Properties. Read more:

Low Carbon Steel Vs High Carbon Steel

www.mnypca.orgNormalised Carbon Steel | DoITPoMS, University Of Cambridge … | Flickr

www.mnypca.orgNormalised Carbon Steel | DoITPoMS, University Of Cambridge … | Flickr

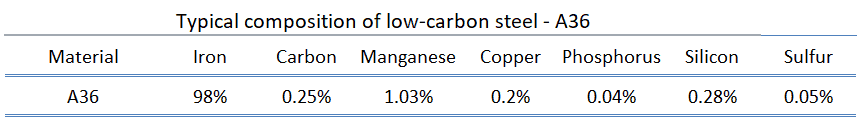

flickr.comWhat Is Composition Of Low-carbon Steel - Definition | Material Properties

flickr.comWhat Is Composition Of Low-carbon Steel - Definition | Material Properties

material-properties.orgsteel

material-properties.orgsteel

What Are Properties Of Medium-carbon Steel - Definition | Material

material-properties.orgalloys steels nuclear hardness motorservice cigüeñales kurbelwellen costs kurbelwelle gears

material-properties.orgalloys steels nuclear hardness motorservice cigüeñales kurbelwellen costs kurbelwelle gears

How To Identify Carbon Steel By Grinding-Low Or High Carbon #

www.youtube.comWhat are properties of medium-carbon steel. How to identify carbon steel by grinding-low or high carbon #. What is composition of low-carbon steel

www.youtube.comWhat are properties of medium-carbon steel. How to identify carbon steel by grinding-low or high carbon #. What is composition of low-carbon steel